High-Flow Sampler Design and Testing Articles

Several manuscripts that describe a high-flow sampler to be used as a personal, integrated inhalable aerosol sampler have been published. The sampler was designed to mimic the operation of the classic 37-mm closed-face cassette to increase adoption by field hygienists while sampling with an efficiency that matches human inhalation of particles.

The first paper describes computational fluid dynamics investigations that identified the optimal design for this sampler:

Sampling Efficiency of Modified 37-mm Sampling Cassettes Using Computational Fluid Dynamics

T. Renée Anthony, Darrah K Sleeth, and John Volckens

Published in the Journal of Occupational and Environmental Hygiene, available at:

http://oeh.tandfonline.com/doi/pdf/10.1080/15459624.2015.1091961

ABSTRACT

In the U.S., most industrial hygiene practitioners continue to rely on the closed-face cassette (CFC) to assess worker exposures to hazardous dusts, primarily because ease of use, cost, and familiarity. However, mass concentrations measured with this classic sampler underestimate exposures to larger particles throughout the inhalable particulate mass (IPM) size range (up to aerodynamic diameters of 100 μm). To investigate whether the current 37-mm inlet cap can be redesigned to better meet the IPM sampling criterion, computational fluid dynamics (CFD) models were developed, and particle sampling efficiencies associated with various modifications to the CFC inlet cap were determined. Simulations of fluid flow (standard k-epsilon turbulent model) and particle transport (laminar trajectories, 1–116 μm) were conducted using sampling flow rates of 10 L min−1 in slow moving air (0.2 m s−1) in the facing-the-wind orientation. Combinations of seven inlet shapes and three inlet diameters were evaluated as candidates to replace the current 37-mm inlet cap. For a given inlet geometry, differences in sampler efficiency between inlet diameters averaged less than 1% for particles through 100 μm, but the largest opening was found to increase the efficiency for the 116 μm particles by 14% for the flat inlet cap. A substantial reduction in sampler efficiency was identified for sampler inlets with side walls extending beyond the dimension of the external lip of the current 37-mm CFC. The inlet cap based on the 37-mm CFC dimensions with an expanded 15-mm entry provided the best agreement with facing-the-wind human aspiration efficiency. The sampler efficiency was increased with a flat entry or with a thin central lip adjacent to the new enlarged entry. This work provides a substantial body of sampling efficiency estimates as a function of particle size and inlet geometry for personal aerosol samplers.

These images show how small (1 μm) and large (74 μm) particles travel through the air and into two of the inlet shapes studied.

The second paper describes the development and testing of the prototype sampler, selected as the thin, central lip sampler in the above paper.

A Simple and Disposable Sampler for Inhalable Aerosol

Christian L'Orange, Kimberly R. Anderson, Darrah K. Sleeth, T. Renée Anthony, and John Volckens

Published in the Annals of Occupational Hygiene, available at:

http://annhyg.oxfordjournals.org/content/60/2/150.full.pdf+html

ABSTRACT

The state-of-the-art for personal sampling for inhalable aerosol hazards is constrained by issues of sampler cost and complexity; these issues have limited the adoption and use of some samplers by practicing hygienists. Thus, despite the known health effects of inhalable aerosol hazards, personal exposures are routinely assessed for only a small fraction of the at-risk workforce. To address the limitations of current technologies for inhalable aerosol sampling, a disposable inhalable aerosol sampler was developed and evaluated in the laboratory. The new sampler is designed to be less expensive and simpler to use than existing technologies. The sampler incorporates a lightweight internal capsule fused to the sampling filter. This capsule-filter assembly allows for the inclusion of particles deposited on the internal walls and inlet, thus minimizing the need to wash or wipe the interior sampling cassette when conducting gravimetric analyses. Sampling efficiency and wall losses were tested in a low-velocity wind tunnel with particles ranging from 9.5 to 89.5 μm. The results were compared to the proposed low-velocity inhalability criterion as well as published data on the IOM sampler. Filter weight stability and time-to-equilibrium were evaluated as these factors affect the practicality of a design. Preliminary testing of the new sampler showed good agreement with both the IOM and the proposed low-velocity inhalability curve. The capsule and filter assemblies reached equilibrium within 25h of manufacturing when conditioned at elevated temperatures. After reaching equilibrium, the capsule-filter assemblies were stable within 0.01mg.

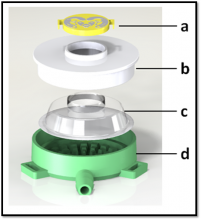

This illustration shows a rendering of the prototype sampler:

Another paper describes the field performance of this sampler compared to IOMs when used as area samplers.

Performance of Prototype High-Flow Inhalable Dust Sampler in a Livestock Production

T. Renée Anthony, Changjie Cai, John Mehaffy, Darrah Sleeth, John Volckens

Published in Journal of Occupational and Environmental Hygiene, available at:

http://www.tandfonline.com/doi/full/10.1080/15459624.2016.1240872

ABSTRACT

A high-flow inhalable sampler, designed for operational flow rates up to 10 L/min using computer simulations and examined in wind tunnel experiments, was evaluated in the field. This prototype sampler was deployed in collocation with an IOM (the benchmark standard sampler) in a swine farrowing building to examine the sampling performance for assessing concentrations of inhalable particulate mass and endotoxin. Paired samplers were deployed for 24-hours on 19 days over a three-month period. On each sampling day, the paired samplers were deployed at three fixed locations and data were analyzed to identify agreement and to examine systematic biases between concentrations measured by these samplers. Thirty-six paired gravimetric samples were analyzed; insignificant, unsubstantial differences between concentrations were identified between the two samplers (p=0.16; mean difference 0.03 mg/m3). Forty-four paired samples were available for endotoxin analysis, and a significant (p=0.001) difference in endotoxin concentration was identified: the prototype sampler, on average, had 120 EU/m3 more endotoxin than did the IOM samples. Since the same gravimetric samples were analyzed for endotoxin content, the endotoxin difference is likely attributable to differences in endotoxin extraction. The prototype’s disposable thin-film polycarbonate capsule was included with the filter in the 1-hour extraction procedure while the internal plastic cassette of the IOM required a rinse procedure that is susceptible to dust losses. Endotoxin concentrations measured with standard plastic IOM inserts that follow this rinsing procedure may underestimate the true endotoxin exposure concentrations. The maximum concentrations in the study (1.55 mg/m3 gravimetric, 2328 EU/m3 endotoxin) were lower than other agricultural or industrial environments. Future work should explore the performance of the prototype sampler in dustier environments, where concentrations approach particulates not otherwise specified (PNOS) limits of 10 mg/m3, including using the prototype as a personal sampler.

This illustrates the prototype sampler, with the disposable capsule bonded to the Teflon filter (center bottom).

Assessment of Increased Sampling Pump Flow Rates in a Disposable, Inhalable Aerosol Sampler

Justin Stewart, Darrah K. Sleeth, Rod G. Handy, Leon F. Pahler, T. Renee Anthony, and John Volckens

Published in the Journal of Occupational and Environmental Hygiene, available at:

http://www.tandfonline.com/doi/full/10.1080/15459624.2016.1237028

ABSTRACT

A newly designed, low-cost, disposable inhalable aerosol sampler was developed to assess workers personal exposure to inhalable particles. This sampler was originally designed to operate at 10 L/min to increase sample mass and, therefore, improve analytical detection limits for filter-based methods. Computational fluid dynamics modeling revealed that sampler performance (relative to aerosol inhalability criteria) would not differ substantially at sampler flows of 2 and 10 L/min. With this in mind, the newly designed inhalable aerosol sampler was tested in a wind tunnel, simultaneously, at flows of 2 and 10 L/min flow. A mannequin was equipped with 6 sampler/pump assemblies (three pumps operated at 2 L/min and three pumps at 10 L/min) inside a wind tunnel, operated at 0.2 m/s, which has been shown to be a typical indoor workplace wind speed. In separate tests, four different particle sizes were injected to determine if the sampler’s performance with the new 10 L/min flow rate significantly differed to that at 2 L/min. A comparison between inhalable mass concentrations using a Wilcoxon signed rank test found no significant difference in the concentration of particles sampled at 10 and 2 L/min for all particle sizes tested. Our results suggest that this new aerosol sampler is a versatile tool that can improve exposure assessment capabilities for the practicing industrial hygienist by improving the limit of detection and allowing for shorting sampling times.

Prototype samplers positioned on mannequin during wind tunnel study.